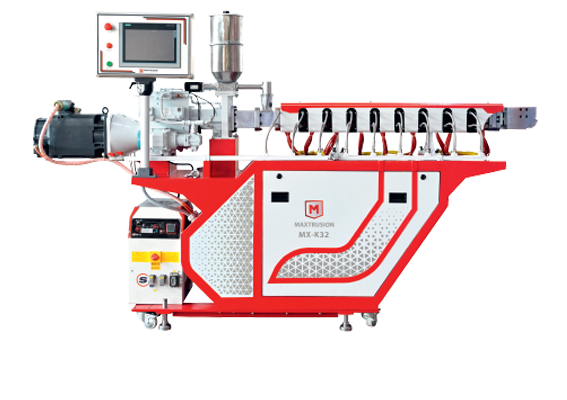

The twin screw compounder MX-K32 is a highly flexible and efficient system designed for continuous mixing, compounding, and processing of polymers with various additives. It provides excellent dispersion, consistent quality, and high throughput thanks to its co-rotating twin screw technology. This machine is commonly used in the production of masterbatches, engineering plastics, filler compounds, and other specialty materials.

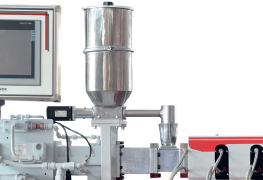

The main feeder supplies base material to the feed zone at a stable and precise rate for consistent processing.

The side feeder adds fillers, fibers or masterbatches mid-process, with easy disassembly for quick change-overs.

Degassing removes moisture, volatiles, and gases via vacuum vents for consistend and stable operation.

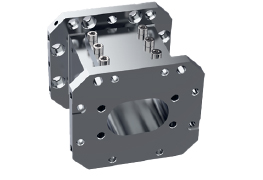

Our twin screws have modular elements for flexible setup, easy maintenance, and segment replacement.

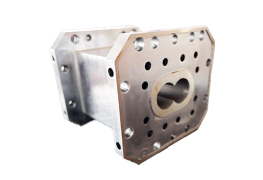

The barrel has modular sections for key stages, allowing easy up-keep and quick adaptation.

PLC–HMI controls speed, temperature, vacuum, and torque, with recipe monitoring and optimization.