Our monofilament lines ensure consistent results for different industry segments including brushes, textiles, as well as industrial applications, helping you achieve the highest standards in quality. With our multifilament solutions you will elevate your product appeal and functionality. It combines performance with design flexibility.

The gravimetric dosing system EXAKTFEED, together with the extrusion control system enable very precise feeding of material.

Designed for testing and developing of new materials as well as production of standard filaments, with a Die Head Nozzle 1.3: 3 mm.

The water path cools the filament after the extruder process and before reaching the spooler. It includes speed control system for consistent and stable operation.

Contactless laser thickness measurement and control system with advanced software to ensure perfect roundness and optimum dimensional accuracy.

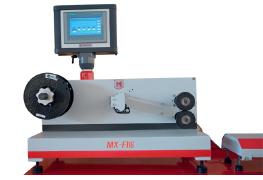

The spooler allows winding the extruded filament and also defines the filament diameter by adapting the speed of puller wheels.

The air bath cools the extruded filament with adjustable airflow, ensuring gradual cooling, dimensional stability, reduced internal stress, and consistent roundness.